952-913-8880

Each engineered tissue requires a unique set of culture growth conditions to optimize outcomes. Our customers often spend decades perfecting the tissue culture “recipe” of cells/biomaterials/culture medium, bioreactor chamber, and mechanical loading and fluid flow conditions. Recognizing these efforts and the drawbacks of switching to a different bioreactor chamber, we have developed bioreactor drive systems that connect to your existing bioreactor chamber.

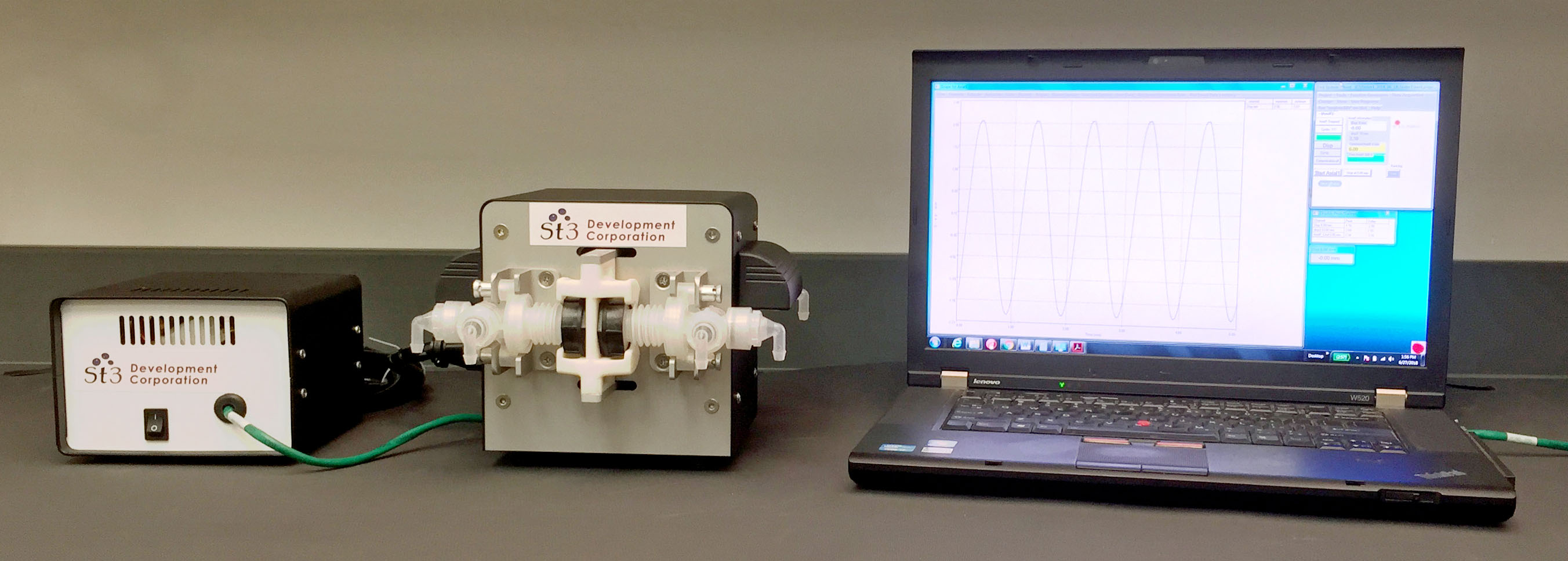

You can now leverage your current bioreactor chamber design and prior data, while taking advantage of a robust, fully-automated and scalable bioreactor drive system. Each oscillatory flow bioreactor drive system can have up to 4 pump cartridges installed that can connect to 4 customer-provided bioreactor chambers. Multiple drive systems can be controlled by a single laptop computer, and each drive system can have a different stimulation waveform profile.

Oscillatory Flow Bioreactor Drive System Specifications | |

Pump Cartridges - Flow Loops | 1, 2, 3 or 4 |

Pump Cartridge Volumetric Output per mm of Displacement | 0.5 ml/mm for ± 6.0mm displacement |

Pump Cartridge Design | Double Integrated Checkvalve (Checkvalves are removable) |

Displacement Transducer Type | LVDT Non-Contacting |

Pressure Transducer Calibrated Output Range | +/-350 mmHg |

Laptop Operating System | Windows 10 |

BDS Linear Drive Output Frequency Range | 0 to 10Hz |

BDS Linear Drive Waveform Types | Sine, Triangle, Square, Ramp and Block |

BDS Controller Output Channels - Two (2) | · Drive signal to the Linear Motor · Digital Output to Motor Amp |

BDS Controller +/-10V Analog Input Channels - Eight (8) | · Displacement · Press1 · Press2 · Press3 · Press4 · Laser · Aux1 · Aux2 |

BDS Input Voltage | 100-240VAC |

BDS Input Power | 60W |